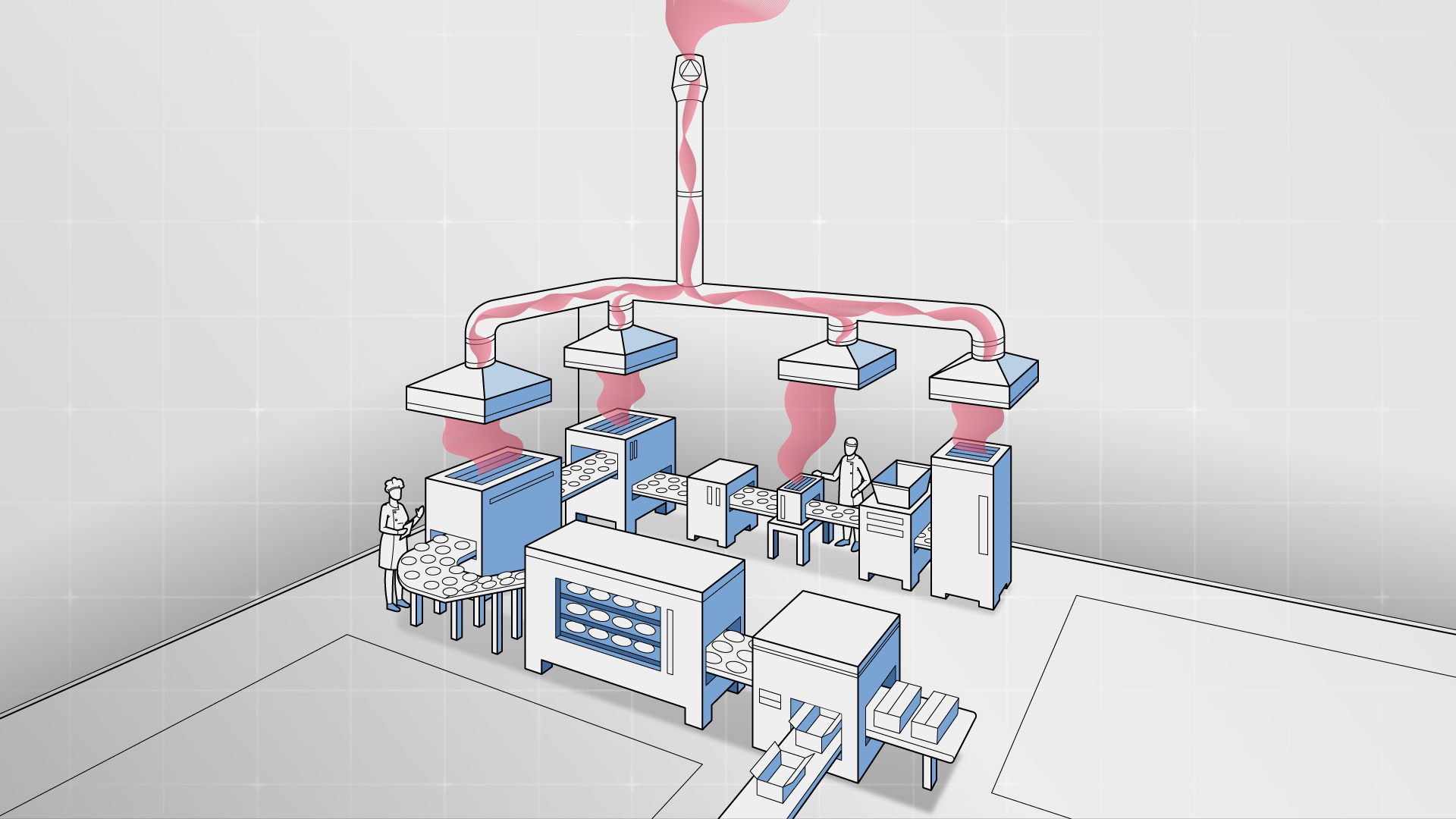

In all buildings where there is an ongoing process, the air gets polluted and is ventilated out of the building via process ventilation. Due to the pollutants in the exhaust air, this hot air is currently being ventilated without any energy recovery. This is because traditional heat exchangers are not able to cope with pollutants.

The result is a massive waste of energy/money/CO2.

.png?width=1200&height=627&name=Without%20energy%20recovery%20(2).png)

Examples of plants where there is process ventilation and there is an ongoing waste of energy

Polymer factories (particles)

Restaurant ventilation (Grease and soot)

- Industrial laundries (lint and moisture)

- Food production (grease and moisture)

- Wood dryers (particles)

- Crop dryers (particles)

- Painting (particles)

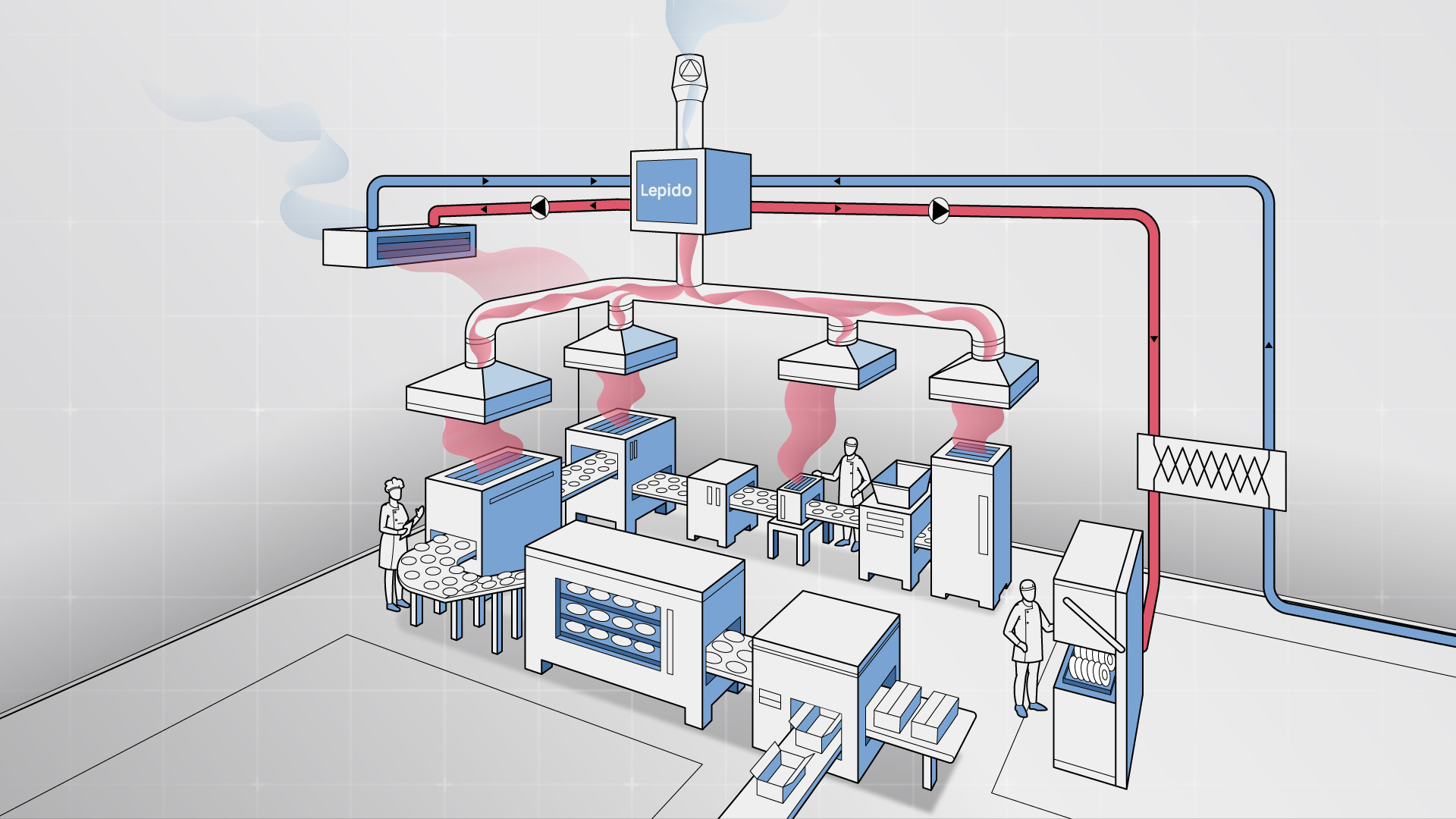

Thanks to our patented design, pollutants in the exhaust air is no longer a problem when it comes to energy recovery.

The recovered heat can be used to heat replacement air, or returned to the process itself by preheating liquid/air.

Areas of Operation

Our technology can be used to recapture excess heat in almost all types of process ventilation. Even in ones not listed below

Industrial Laundries

Industrial and manufacturing companies, workwear, protective gear, Textile rental companies, laundromats, uniform services, hospitals and healthcare facilities

-1.png?width=1200&height=1200&name=Client%20portfolio%20(2)-1.png)

Industrial applications & Foundries

Glass, metal, paint, polymer and rubber manufacturing

Non-residential large complexes

Schools, universities, office cafeterias, food courts, recreational centres, supermarkets and gas stations

Industrial food & beverage production

Industrial bakery items, Dairy Products, Tea & coffee, Alcoholic Beverages, Ethnic & Specialty Foods, Packaged & Processed Food and Pet food

.png?width=1200&height=627&name=Expand%20your%20operations%20Become%20a%20partner%20(3).png)

Snacks production

Instant and Ready-to-Eat, Confectionery and Sweets, Fried or Baked Snacks, Frozen Snacks, Extruded and Processed Snacks and more

Wood, Paper and Pulp Production

Sawmills, Lumber Mills, Wood Processing Plants, kraft pulp, sulfite pulp mills, Mechanical Pulping Plants, Paper & Paperboard Mills, Finishing and Specialty Paper Plants

Meat Processing/ Slaughterhouses

Meat Packing plants, Value-Added Meat Processing Plants, Abattoirs (Slaughterhouses), Butcher Shops, Export Processing Plants

Automotive Industry

Paint shops, metal stamping & forging plants, engine & transmission manufacturing, welding & assembly lines, plastic molding and more

Farming and agriculture

Greenhouses, Animal Housing, Crop Drying, Dairy Farms, Post-harvest processing

Marine and Shipbuilding

Commercial Shipping, Cruise and Passenger Ships, Marine Construction and Dredging, Marine Transportation, Galleys (ship kitchens)

Restaurants and fast food franchises

Quick Service Restaurants (QSRs), Buffets, Cafes, Bakeries, Pizzerias & more

.jpg?width=1200&height=627&name=Expand%20your%20operations%20Become%20a%20partner%20(3).jpg)

-2.png?width=1200&height=1200&name=Client%20portfolio%20(5)-2.png)

-1.png?width=1200&height=1200&name=Client%20portfolio%20(5)-1.png)